WOOD PRODUCTS

EW

Extended Wax

1Challenge

Develop an innovative evolution to wax emulsion technology by creating a natural, bio-

based extended wax that exceeds various wood (OSB, MDF, particleboard) safety and

performance standards and delivers comparable, or enhanced, performance.

2Objective

Create a value-added product for the industry. We set out to design an industrial wax that is

not derived from fossil fuels and saves the customer time, money, resources and improves

performance and safety.

Example of wax emulsion droplets on a wood surface.

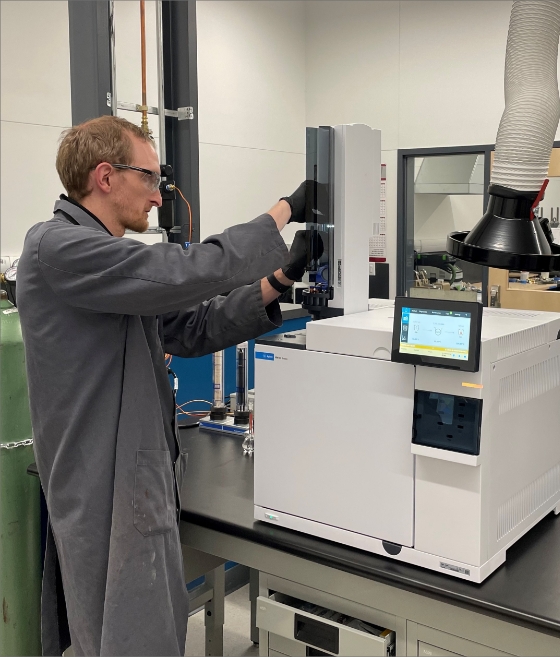

WVCO Chemist working on understanding molecular morphology of wax for engineering optimum product for the customers.

3Approach

We set out to invent the perfect

solution for the customer’s needs.

Starting with a control formula we began evaluating a variety of extender

materials and ration options. Leveraging our expertise with two-

component mixtures in polyurethane and dispensing of chemicals, we

refined the product through comprehensive testing, including:

Wax volatility testing

to evaluate product

flash point

Reactivity/stability testing

when mixed with pMDI

- – Quantify improved performance

- – Reductions in pMDI

Panel testing

- – Measure volatility reduction

- – Health & safety improvements

Emissions testing

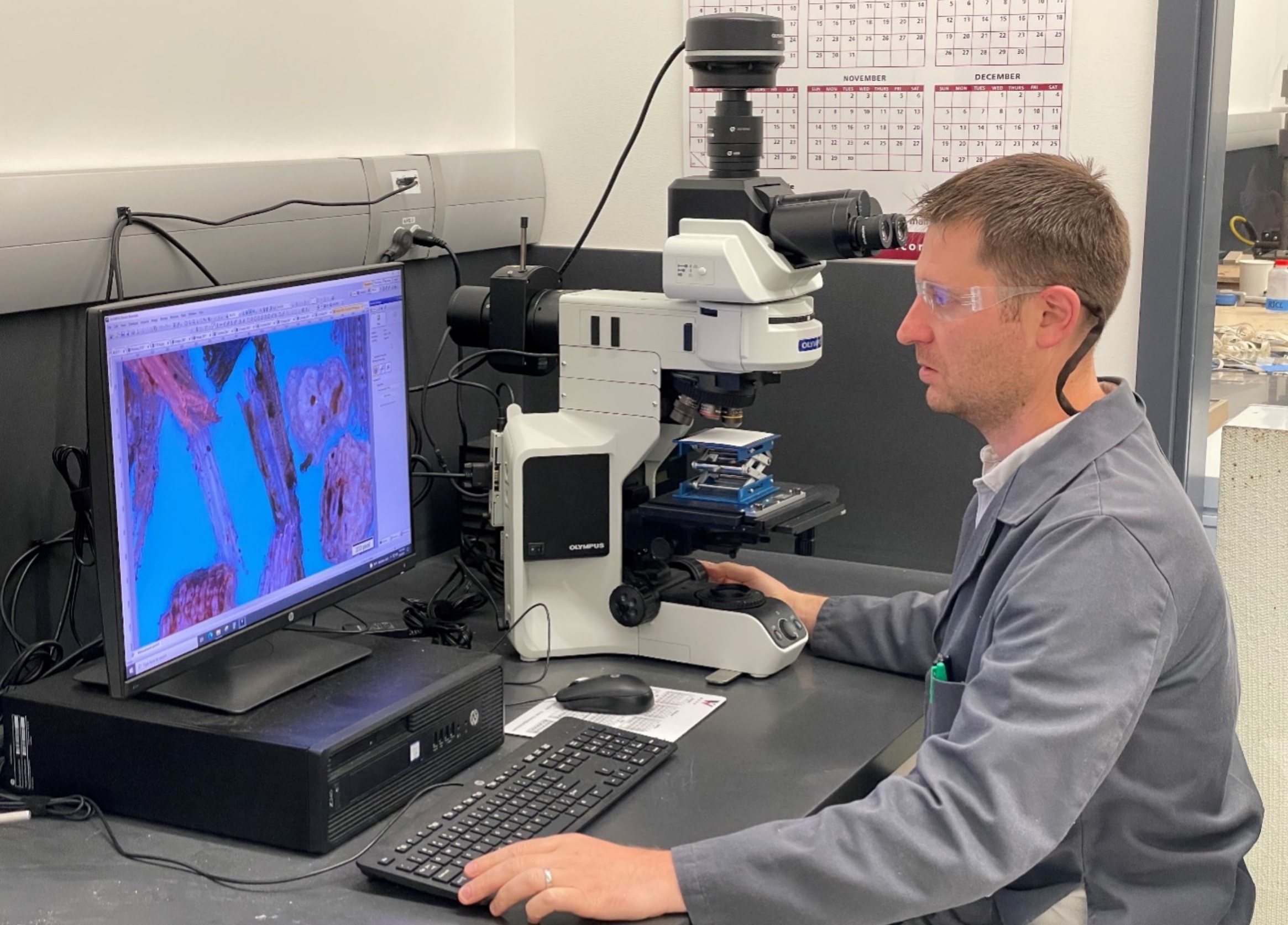

State-of-the-art microscopy to investigate wood-wax interaction and its impact on composite performance.

4Solution

We created a value-added wax emulsion that uses a bio-based extender to offset at least 20% wax based on non-renewable chemical feed stocks.

This innovative product represents a breakthrough for the

market — as a stand-alone product, the formula offers

increased benefits, but when mixed with a pMDI it offers an

additional suite of benefits.

Superior pMDI and wax distribution on OSB flakes causing improved adhesion and moisture durability. The picture shows a representative OSB strand with pMDI-EW spray distribution.

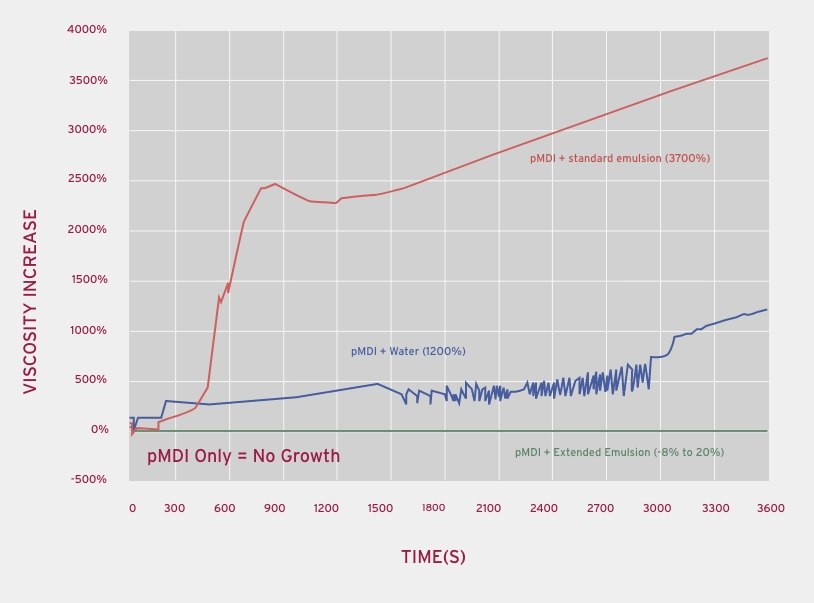

The extended wax is engineered to provide chemical stability when mixed with pMDI causing minimum or no pre-mature curing. Regular wax emulsion and water causes drastic pre-mature reaction with pMDI causing failure. The time-domain viscosity data shown above.

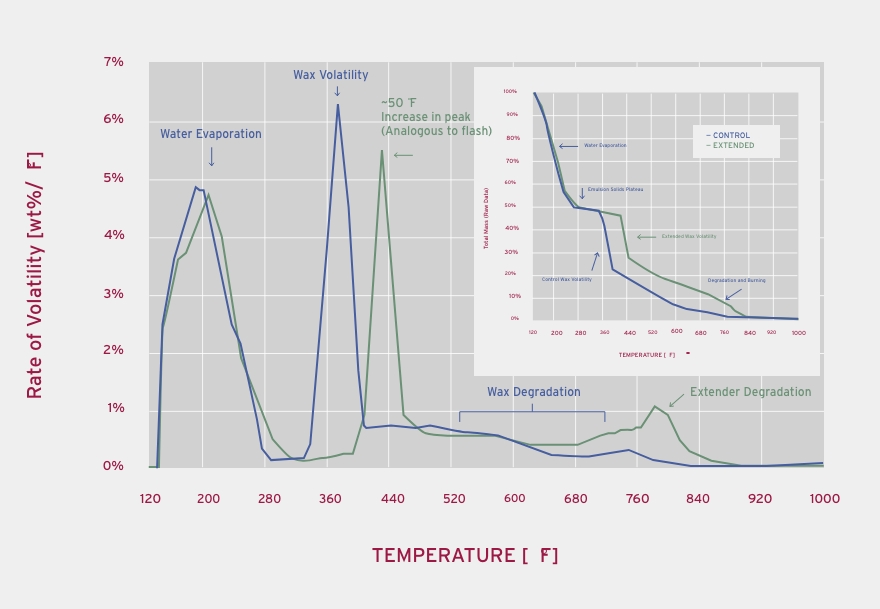

Thermogravimetric analysis (TGA) of regular and EW emulsion showing ~ 50 F rise in peak volatility. The EW emulsions has reduced volatility as compared to its parent wax emulsion, making it safer and better performing.

5Outcomes

Lower volatility / increased

flash point

- – Safer

- – Better performance

Improved product

performance

- – Moisture durability (wax and adhesive)

- – Mechanical performance (adhesive)

- – Better waxes can be used

- – Resin and wax savings afforded by increased performance

Ability to be co-applied with

pMDI resin

- – Improved distribution for wax and resin

- – Reduction in pMDI volatility (safety & maintenance)

More environmentally

friendly

- – 20% reduction in wax solids

Value-Added (Extended) Wax

HPRE

See how we created a solution that was electrically isolating, reduced noise and vibration…

VIEW NEXT INNOVATION