What Are the Most Common Uses For FastPatch®?

“We are using FastPatch® to repair cracks, spalls, and joints. One product for all the repairs and from the same machine. We don’t have to handle any material during our shift since it comes in 250 gallon totes, which saves us a lot of time.” – DOT Supervisor

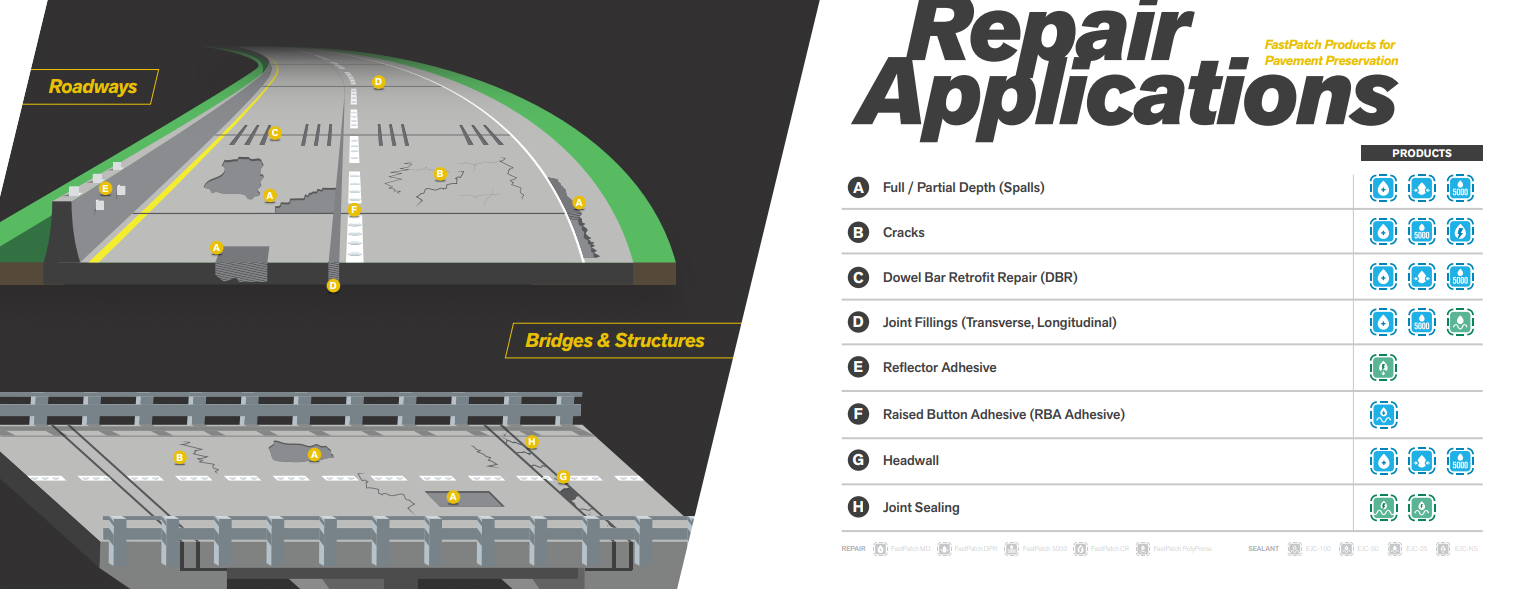

By now, you may have read about WVCO’s unique polymer repair system, FastPatch®, and why it’s commonly used by DOTs and transportation professionals from all over the United States and around the world to repair airports, highways, bridges, railroads, and other various applications. Transportation professionals rely on FastPatch® for its ease-of-use, dependability, and versatility. However, what you may not understand is HOW it is used.

FastPatch® is most commonly used to repair broken concrete and asphalt, spalls, potholes, joints, driveways, highways, bridge decks, parking lots, cracks, slab repairs, ramps and loading docks, warehouse floors, post anchors, and trip hazards. When installed properly, this pavement preservation solution will last longer than the life of the pavement. Not to mention, it bonds tenaciously to surfaces and remains flexible throughout its service life.

Here are some questions that we often get about FastPatch and its most common uses.

How is FastPatch® applied?

FastPatch® is packaged in cartridges, kits, drums, and totes. Choose the package type that matches the accessibility of the repair area, and minimize the waste or handling of multiple packages. For example, have several 3-gal FastPatch DPR Kits available, so you can use it for a smaller repair instead of wasting half of a 5-gal kit. You’ll learn the proper steps and procedures for the metering systems by following these tutorials.

Are FastPatch® repairs environmentally safe?

Yes. FastPatch® uses recycled and renewable materials to repair existing materials. It is 100% solids and does not contain any volatile chemicals. Repairing with FastPatch, rather than removal, eliminates disposal costs and excess waste.

Which product do I use to fill a joint to seal it and keep water out?

EJC-100 with PolyPrime is the best combination to handle exterior joint movement and seal it from water. TIP: Use topping sand that blends with the surrounding surface.

Do you have a product that can fill joints on a slope or vertical?

Yes. For slope grade application, ask for the SG version of EJC-100. For vertical joints, consider the EJC-NS. For ramps, use the FastPatch® DPR and extend it with dry, clean sand until the consistency is correct for the slope.

I want to repair concrete and asphalt. Can I do that with FastPatch?

Yes. FastPatch DPR Kit can be used for both distressed pavement repairs. The kit comes with colored topping sand. FastPatch can also be machine dispensed from drums or totes to repair cracks, joints, and spalls.

What Package Sizes Do You recommend?

For smaller repairs, including repairs to joints and cracks, FastPatch® cartridges are an easy and durable solution. For medium-sized repairs of concrete or asphalt in a short period, the Kit packaged or machine-dispensed products are a fine choice for a quick return to service. If you have a large repair project, machine-dispensed FastPatch products are ideal for completing larger repairs or multiple repairs in a single shift, without having to handle material or containers.

What tools will I need to install FastPatch Kits?

CLEAN and DRY the repair area with a high velocity and CFM blower (250 MPH / 700 CFM) blower or dry compressed air (120 CFM / 90 psi). Use a propane field torch to DRY area if moisture is present. 2. 1/2 in. Corded drill. Mud mixer drills work well. 3. Egg-Beater style pail mixer 4. Trowel. 5. Personal protection—safety glasses, skin protection, and gloves. 6. Towels for cleaning mixer and tools. 7. Optional: Tape for protecting edges of the repair area. Broom for clean-up.

Is a bond agent or primer required?

Depends on the application and product. Bonding agents reinforce the repair area and help promote the adhesion of the repair material. FastPatch® DPR Kits are typically applied without a bonding agent since the first layer in the repair area is very fluid and when it cures, it has excellent adhesion. The EJC Sealant product typically requires a bonding agent to reinforce the joint walls and maximize the movement capabilities under thermal movement in exterior joints.

As a Contractor, how can I find out more information about using FastPatch on future projects? Contact us at FastPatch@wilvaco.com or 800-333-9826 and check out some of our case histories.

Click here for more answers to commonly asked questions or

download our brochure.

SOURCES

RELATED ARTICLES

What can

Willamette Valley

Company do for

you today?

Willamette Valley Company offers some of the most innovative wood products solutions in the industry, including patches, fillers, extenders, coatings, inks, abrasives, tapes, and a wide variety of outstanding application equipment and parts.

Find Out Now